Bulk Transport

Tanker washout wastewater is from tanker cleaning facilities where an extremely wide variety of transported liquid products are washed from the tankers in preparation for the tanker receiving the next load. Tanker cleaning falls into several categories; Food Grade, Chemical Grade, and Specialty Grade. Tankers carry everything from corn syrup to paint pigment.

Design Considerations

Tanker cleaning wastewater is difficult to treat mostly because the wastewater strength and composition regularly changes depending on the mix of tankers being washed that day. Add to that the detergents, sanitizers and in the case of chemical grade, various solvents are often used.

The wastewater typically contains an emulsion that must be broken, followed by precipitation, coagulation, flocculation and flotation separation. A mixed/aerated equalization tank ahead of the wastewater treatment system is necessary to store and homogenize the wastewater which will smooth out the operation of the system.

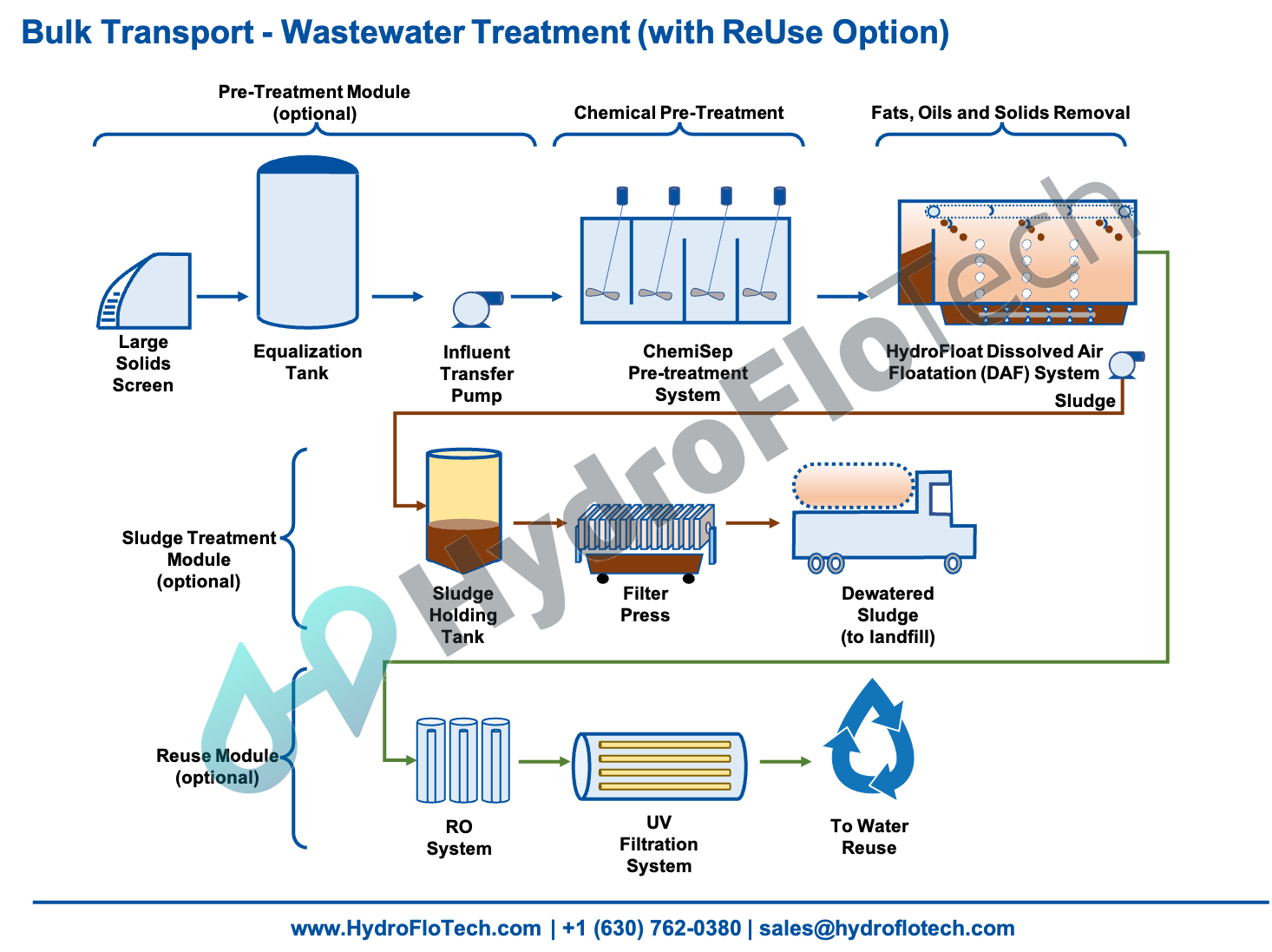

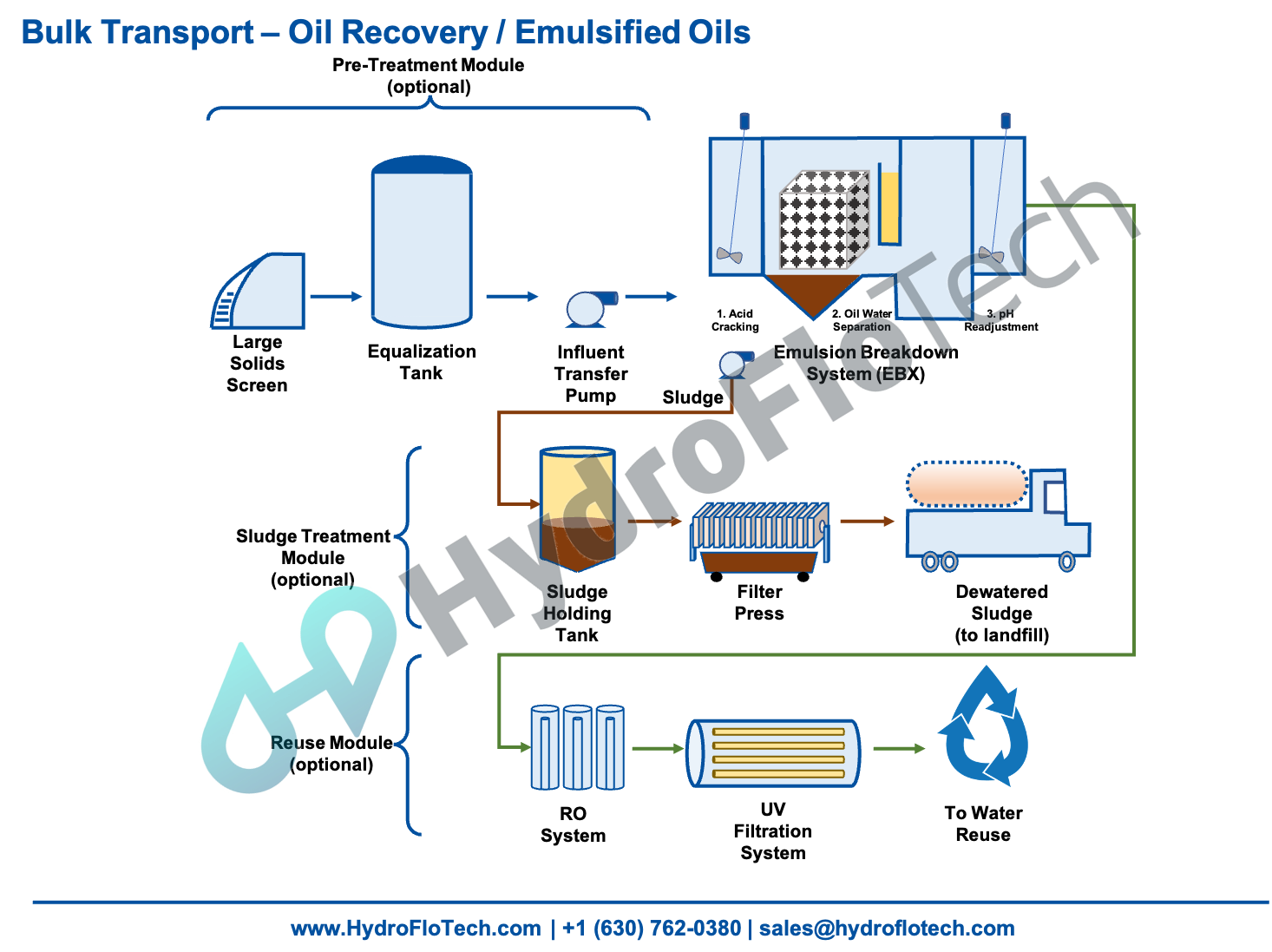

HydroFloTech has designed a fully modular system for treating and possibly recycling wastewater from tanker, truck and railcar wash systems:

Pre-Treatment Module: This module removes large solids and equalizes the water prior to any further treatment. The goal of this module to get the water provide the downstream treatment equipment with an equalized stream of water which if free from large solids.

Side Hill Screen / Grit Removal System: “Side hill” or “Grit Removal Systems” are used for the removal of large insoluble material from wastewater flows. These screens or systems are used on process and wastewater streams for particles that need to be removed to protect downstream systems. These screens can also be used for product recovery; large solids separation and mixed settleable solids for both municipal and industrial applications.

The HydroFloTech Side Hill Screen or Grit Removal System maximize solids removal in an easy to maintain unit. The screen is a barrier by which material larger than the gap or slot size may not pass, allowing the water to continue through.

Equalization Tank: HydroFloTech can work with an existing equalization “EQ” tank or provide one. Materials of construction can includes: Fiberglass (FRP), HDPE, steel (carbon steel or stainless steel), concrete, or even in-ground storage pits / ponds. The purpose of the equalization tank is to “equalize” and narrow any variances in water characteristics. The EQ tank also acts as a great buffer for two main purposes: First the EQ tank provides a buffer storage capacity in situations when there is a temporary surge in flowrate. This allows the system to be smaller than the peak surge flowrate. Secondly, the EQ tank also provides the ability to “narrow” any spikes in any contaminants.

Option 1: Emulsified Oil Removal System

When the wastewater has emulsified (mechanically or chemically) oils, those emulsions need to be broken in very specific ways. The following process may be utilized:

Step 1: “Acid Cracking” / “Acidulation” / Acid Injection

In this chamber, an acid injection pump pulses and doses the right amount of acid to drop the pH of the water to “crack” or “break” the emulsified compounds of oil into free floating oils. A pH probe and a mixer in the chamber ensure uniformity while the tank is sized appropriately for the required retention times.

Step 2: Oil Water Separator

In this chamber, free oils (and in some cases solids that drop out as sludge) are separated from the water. The free oil, with its specific gravity being lower than water, will flow to the top. As water flows through the separation chamber, oil particles stay attached to the media while water flows through the unit. As oil accumulates, it will flow to the top and will be captured through a weir system. The sludge collection chamber shall be located directly beneath the coalescing media pack and provide ample storage capacity for the settled sludge. The sides of the chamber are sloped at 45 degrees to insure easy and complete removal of the settled sludge.

Step 3: pH Re-Adjustment

In this chamber, the pH is re-adjusted to a neutral (or any other desired) levels to allow for any further treatment or usage. Given that the lower pH that is required during “acid cracking”, the water is not suitable for most discharge / reuse purposes. As a result, pH is readjusted higher by automatically injecting caustic in this chamber. Similar to the automated system in Step 1 required for acid injection, a pH probe and a mixer are included in this chamber to ensure uniformity while the tank is sized appropriately for the required retention times.

Option 2: Oils and Solid Removal System

When the wastewater has oils and other contaminants that needs to be treated, the following process may be utilized:

Chemical Pre-Treatment and Solid Removal: This module chemically treats the water with pH adjustment (as necessary), coagulant and polymers to enhance the ability of HydroFloTech inclined plate clarifiers or dissolved air floatation systems (DAF) to effectively remove any Total Suspended Solids (TSS) or Fats, Oils and Grease (FOG).

ChemiSep Chemical Pre-Treatment System: The efficacy of any wastewater is as good as the pre-treatment of the wastewater prior to removal of any impurities. The HydroFloTech ChemiSep Pre-Treatment System provides great flexibility in treating various wastewater profiles:

- Stage 1 – Emulsion Cracking / Acidulation / “Acid Cracking”: pH is lowered to ~3.5 with the pH controller using acid to break any emulsion.

- Stage 2 – Precipitation & Coagulation: pH is raised to 8.5 with the pH controller using caustic while adding a coagulant such as alum or a PAC. A “pin floc” is developed indicating the emulsion and the suspended solids are precipitated.

- Stage 3 – Flash Mix: The wastewater with it’s precipitated pin floc is introduced to the flash mix zone where a polymer flocculent is added. This stage maximizes flocculent dispersion throughout the coagulated wastewater.

- Stage 4 – Flocculation: The wastewater is now introduced to the slow mix zone to agglomerate the floc into larger particles suitable to be enmeshed with the air bubbles.

HydroFloat Dissolved Air Flotation (DAF) System: The flocculated wastewater is introduced into the HydroFloat DAF System inlet where the particles are comingled with a pressurized dissolved fine bubble recycle stream. The floc particles attach to the bubbles and float to the surface where they are mechanically skimmed into the float scum sludge chamber. The clarified treated water then exits the end of the DAF and flows downstream to sewer or further treatment if necessary. The DAF system bubbles come from a Recycle Air Dissolving system that takes a portion of treated effluent, pressurizes it and introduces air to be dissolved. The dissolved air comes out of solution and forms a fine bubble stream when the pressure is released at the DAF entrance in the presence of floc wastewater.

Sludge Management System: This module removes the precipitated solids from the water and converts those solids into dewatered “sludge” which may be eligible for re-use or landfill disposal.

Sludge Tank with Sludge Transfer Pump: The accumulated sludge is periodically removed from the clarifier and sent to a sludge holding tank where it further thickens for disposal or dewatering.

Sludge Dewatering: Sludge dewatering is typically handled by a HydroPress Filter Press or Screw Press. After processing a batch of “sludge” the filter press or screw press is emptied of “chrome cake” which is a semi solid of approximately 20-35 % solids. Chrome cake is high in chrome and sulfite and should be disposed of according to environmental regulations.

Re-Use Module: This module further reduces any remaining solids and biological / bacterial growth in the water to make it suitable for re-cycling or re-use.

RO System: The RO System removed any remaining dissolved solid (TDS) in the wastewater. The effluent coming out of the RO System is suitable for re-cycling / re-use.

UV Filter System: The UV Filter System finishing a final sanitizing of the water. The UV Filter System allows for the treated water to be used for most re-use / recycling purposes.